|

| September 03, 2019 | Volume 15 Issue 33 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Air Force develops high-strength, low-cost steel alloy for 3D printing

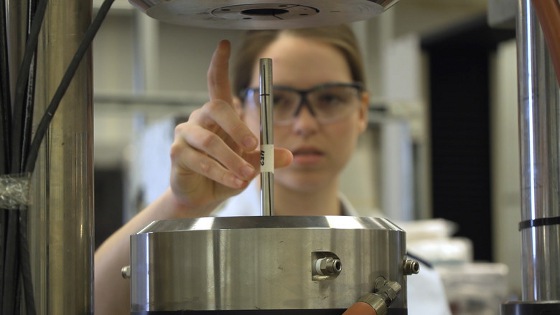

After printing various parts with the AF-9628 steel alloy powder, Capt. Erin Hager analyzed the resulting porosity, strength, and impact toughness. She noted that the mechanical properties were quite good, very similar to traditionally manufactured parts, and met or exceeded specifications straight out of the machine. [Photo courtesy: Air Force Institute of Technology]

By Whitney Wetsig, Air Force Research Laboratory

Parts additively manufactured (AM) with AF-9628, an Air Force steel, are about 20 percent stronger than conventional AM alloys, in terms of ultimate tensile strength, according to research conducted by Capt. Erin Hager, an Air Force Research Laboratory employee and recent graduate of the Air Force Institute of Technology's Aerospace Engineering Program.

AF-9628 is a steel alloy developed by AFRL's Dr. Rachel Abrahams that offers high strength and toughness. The formula, nicknamed Rachel's steel, costs less than some other high-performance steel alloys, including Eglin Steel and HP-9-4-20; however, it is more expensive than common grades used in conventional munitions. AF-9628 is unique since it does not contain tungsten, like Eglin Steel or cobalt, part of the formula for HP-9-4-20, which is in the Massive Ordnance Penetrator, a 30,000-lb bomb that destroys assets in well-protected facilities.

Hager's research, sponsored by the Air Force Research Laboratory Munitions Directorate at Eglin AFB, Florida, determined that AF-9628 is an optimal material for additive manufacturing due to its high strength. While these findings are comparable to values reported in a similar U.S. Army Combat Capabilities Development Command Army Research Laboratory study, Hager yielded similar mechanical properties to conventionally forged and heat-treated AF-9628. Dr. Sean Gibbons, a research materials engineer with the Munitions directorate with expertise in steel, describes this finding as "exciting."

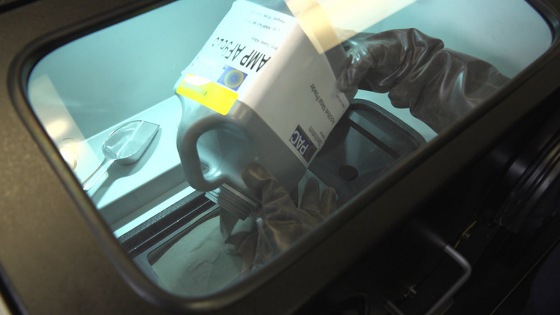

In working with Rachel's Steel, Hager employed powder bed fusion, a type of additive manufacturing in which a laser selectively melts powder in a pattern to create three-dimensional objects. As each layer is complete, the printer dispenses more powder on the build area, and the process continues until the part is complete.

"To determine if AF-9628 was printable, we characterized the shape and size of the powder and [identified] how it changed with melting and sieving," Hager says. She examined it under a scanning electron microscope at AFIT and performed tests at the University of Dayton Research Institute using a size-characterizing light microscope.

Hager provided the chemical composition of AF-9628 steel to Powder Alloy Corp., a manufacturer in Cincinnati, OH. Once she received the powder and determined that it melted predictably in the machine, she moved on to creating actual test articles. After printing various parts, she analyzed the resulting porosity, strength, and impact toughness.

She says that many "alloys don't take to [additive manufacturing] very well." For instance, "certain alloys will not melt, and they crack a lot once you actually try to make a part." However, when Hager examined her parts, she noted that the mechanical properties were "quite good." She found no evidence of cracking and described the output as "very similar to traditionally manufactured parts."

After a more thorough examination, she determined that the parts "matched the required 10 percent elongation indicating increased strength without becoming brittle." Hager explains that the parts "met or exceeded [specifications] straight out of the machine."

Capt. Hager pours the powdered form of AF-9628 steel into a powder bed fusion machine. In this type of additive manufacturing, a laser selectively melts powder in a pattern to create three-dimensional objects. As each layer is complete, the printer dispenses more powder on the build area, and the process continues until the part is complete. Once Hager verified that the powder melted predictably in the machine, she began creating actual test articles. [Photo courtesy: Air Force Institute of Technology]

After she successfully created simple parts, Hager began printing complex designs including several intricate projectiles. She used two machines at AFIT and printed about 130 articles including 30 small cylinders, 60 larger cylinders, 20 tensile bars, and 20 impact specimens.

The parts she made are suitable for weapons applications. When the Air Force initially developed AF-9628 for bunker-busting bomb applications, "the original idea was to make the penetrating weapon of the future with exactly the explosive profile desired."

Hager explains that additive manufacturing "allows [engineers] to put weight [on munitions] only where it's needed." Ultimately, this "enables lighter munitions that get just as deep, so [aircraft] can carry more of these weapons," she says.

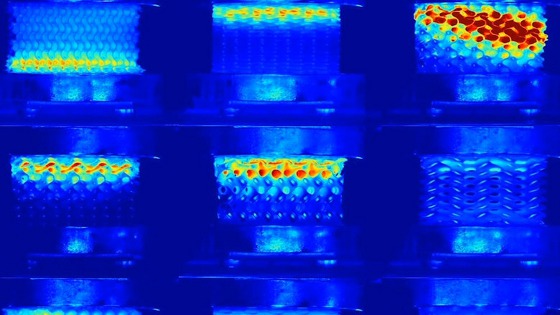

According to UDRI engineers, while additive manufacturing can (in some cases) efficiently fabricate complex shapes at a lower cost than traditional manufacturing, the process can leave residual stresses in parts due to the rapid heating and cooling during the build process.

"Additive is not a precision process so it's difficult to hold geometric tolerances and since the items can come out rough, they sometimes go through a lot of post-processing," says Hager.

Dr. Philip Flater, a mechanical engineer who leads the Munitions directorate additive manufacturing group that sponsored this research, says this can involve polishing and/or heat-treating rough surfaces to resolve material defects like pores and achieve optimal mechanical properties.

While Hager says that roughness and porosity are not ideal qualities in functional parts used repeatedly, components for munitions are single-use items.

Thermal imagery of parts Capt. Erin Hager additively manufactured with AF-9628 powder. [Photo courtesy: Air Force Institute of Technology]

For now, the AF-9628 powder is only available in very small production quantities, and companies can take months to formulate it. As such, while AF-9628 is a less expensive steel, she says that "the powder form does not [currently] result in the same cost savings," since the demand is low.

"It's not very common for customers to request high-strength steels in powder form," she says.

Hager hopes that this early success will lead to increased interest in high strength steels.

"There's not a lot of steels research," she says, adding that ongoing "studies involve mostly titanium and composites."

Hager plans to spread the word about her findings, and she hopes that the Air Force will "take this high-strength steel and come up with some new applications that we haven't even thought of yet." She recently presented her research during an international powder metallurgy conference and an ordnance and ballistics symposium.

Currently, she works within AFRL's Materials and Manufacturing Directorate in the advanced power technology office where she investigates new power technologies that the Air Force can use to reduce costs. As a member of the aviation group, Hager focuses on alternative fuels, light weighting, and drag-reduction measures.

AFRL's Munitions Directorate is leading further research efforts involving additively manufactured munitions. The goal is to create munitions with precision-controlled fragmentation and blast-pressure profiles that minimize collateral damage.

Published September 2019

Rate this article

View our terms of use and privacy policy